Precision Drill Bushings

Bushings have been a backbone of Acme Industrial’s business since 1914. We believe our offerings are the most complete in the industry.

Shop Our Online Store for Pricing and Availability

Standard Bushings

Gun Drill Bushings

Special Purpose Bushings

Toolholder Bushings

Titanium Nitride Bushings

- Is the brittle nature of Carbide Bushings unacceptable for your application?

- Does the quantity of bushings you require for a job make Carbide Bushings cost prohibitive?

- Is the abrasive action of Carbide Bushings causing premature tool wear?

Acme Ultimate Bushings are the answer!

Acme Ultimate bushings are Titanium Nitride (TiN) coated for longer life. Titanium Nitride coated bushings have a hardness of 82-85 RC. This increase in surface hardness means the bushings can stand the abrasive wear of tools and chips for much longer periods of time and are less brittle than regular carbide bushings.

The TiN coating on Acme Ultimate Bushings has a very slippery surface. This slippery surface on the I.D. of the bushing will help increase tool life.

The greater the number of bushings needed for an application, the more Acme Ultimate Bushings can reduce your cost.

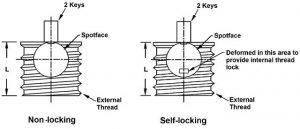

No-Counterbore Bushings

Theirs

- Counterbored

- Case Hardened

Ours

- No Counterbore

Full bearing surface supports the tool for the entire length of bushing. You’ll drill more precise holes plus your Acme bushing will last longer - Hardened

61-65 Rc means less machine downtime to change worn bushings.

Approved by the United States Defense Logistics Agency

Acme Industrial Company has been approved by the United States Defense Logistics Agency as a supplier of Class 3 Threaded Fasteners.