Acme Keylocking Threaded Inserts Compared to Heli-Coil® Inserts

Acme Keylocking Threaded Inserts are often compared to helically wound inserts like Heli-Coil® products, also known as Helicoil products. (Heli-Coil® is a registered trademark of Newfrey LLC.) Both types of insert products are used for thread repair or to bolster the thread strength of the parent material, such as aluminum. Threads in soft materials can be damaged due to wear, stripping or cross threading, necessitating the need for one of these inserts.

The biggest advantages that Acme Keylocking Threaded Inserts have over Heli-Coil® inserts are in pull-out strength, torque-out strength and ease of installation. Heli-Coil® inserts are thread coils made of formed wire while Acme Keylocking Threaded Inserts are machined from solid steel bars.

Installing a Heli-Coil® insert can be difficult and time consuming. It involves drilling and tapping a hole with special drills and taps, inserting the Heli-Coil® insert into a special prewinder tool and lining it up with the tapped hole for installation. Acme Keylocking Threaded Inserts do not need a special prewinder tool or special sized drills or taps.

Heli-Coil® inserts have less pull-out and torque-out strength than Acme Keylocking Threaded Inserts because they are a wound wire versus a solid metal bushing. Cross threading of a Heli-Coil® product is often a problem while accidental cross-threading is nearly impossible with the Acme Keylocking Threaded Insert.

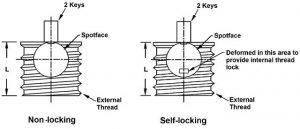

While the Acme Keylocking Threaded Insert is locked into place in the parent material by its locking keys, the Heli-Coil® insert depends on friction to keep it in place. This is not always enough to handle the job and can come out.

Heli-Coil® inserts have tangs that need to be broken off after installation. These broken off tangs can fall into parent material creating FOD (Foreign Object Debris) in the assembly and creating issues for the user.

When an Acme Keylocking Threaded Insert needs to be removed, the material between the keys is drilled out with a standard drill, the keys are bent inward to break off, and a standard screw extractor is used. If a removed insert needs to be replaced, the new insert can be placed into the original tapped hole, but only if the thread of the hole remains intact.

All Acme non industrial inserts are made in the U.S.A. and are DFARS Compliant.