Keylocking Studs Selection Chart

Material:

Insert – A286 CRES (140 KSI Min)

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

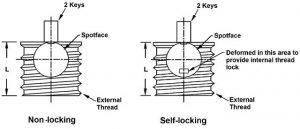

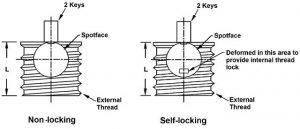

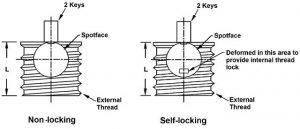

Keys: Inserts with an internal thread size of 5/16 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys.

Material Identification Mark: One line on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51830 & NAS1394)

Material:

Insert – A286 CRES (140 KSI Min)

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Inserts with an internal thread size of 5/16 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys.

Material Identification Mark: One line on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51831& NAS1395)

Material:

Insert – 303 CRES

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Inserts with an internal thread size of 5/16 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys.

Material Identification Mark: None

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51831& NAS1395)

Material:

Insert – A286 CRES (140 KSI Min)

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.25 mm unless specified otherwise

Internal Threads: Per Fed Std H28/21, MJ Form

Dimensions: All dimensions below are in millimeters

Keys: Inserts with an internal thread size of M6 and smaller are furnished with 2 locking keys. Larger sizes have 4 locking keys.

Material Identification Mark: One line on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: NA0149

Material:

Insert – 303 CRES

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.25 mm unless specified otherwise

Internal Threads: Per Fed Std. H28/21, MJ Form

Dimensions: All dimensions below are in millimeters

Keys: Inserts with an internal thread size of M6 and smaller are furnished with 2 locking keys. Larger sizes have 4 locking keys.

Material Identification Mark: None

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: There is no National Aerospace Standard for Metric Keylocking Inserts manufactured from 303 CRES. The inserts are compliant with the other requirements of NA0147, NA1049, and NA0151 except for any references to the type of matrial or performance related to the material.

Material:

Insert – 4140 Alloy Steel (160 KSI Min)

Keys- 302 CRES

Finish: Cadmium Plate (QQ-P-416 Type II, Cl. 2)

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Inserts with an internal thread size of 5/16 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys.

Material Identification Mark: Two lines on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51830 & NAS1394)

Material:

Insert – 303 CRES

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Inserts with an internal thread size of 5/16 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys.

Material Identification Mark: None

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51830 & NAS1394)

Material:

Insert – 4140 Alloy Steel (160 KSI Min)

Keys- 302 CRES

Finish: Cadmium Plate (QQ-P-416, Type II, Cl. 2)

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Inserts with an internal thread size of 5/16 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys.

Material Identification Mark: Two lines on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51831& NAS1395)

Material:

Insert – 303 CRES

Keys- 302 CRESFinish: Passivated

Tolerances: ±.25 mm unless specified otherwise

Internal Threads: Per Fed Std H28/21, MJ Form

Dimensions: All dimensions below are in millimeters

Keys: Inserts with an internal thread size of M6 and smaller are furnished with 2 locking keys. Larger sizes have 4 locking keys.

Material Identification Mark: None

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: There is no National Aerospace Standard for Metric Keylocking Inserts manufactured from 303 CRES. The inserts are compliant with the other requirements of NA0147, NA0149, and NA0151 except for any references to the type of material or performance related to the material.

Material:

Insert – A286 CRES (140 KSI Min)

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.25 mm unless specified otherwise

Internal Threads: Per Fed Std H28/21, MJ Form

Dimensions: All dimensions below are in millimeters

Keys: Inserts with an internal thread size of M6 and smaller are furnished with 2 locking keys. Larger sizes have 4 locking keys.

Material Identification Mark: One line on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: NA0151

Material:

Insert – 4140 Alloy Steel (160 KSI Min)

Keys- 302 CRES

Finish: Cadmium Plate (QQ-P-416 Type II, Cl. 2)

Tolerances: ±.25 mm unless specified otherwise

Internal Threads: Per Fed Std H28/21, MJ Form

Dimensions: All dimensions below are in millimeters

Keys: Inserts with an internal thread size of M6 and smaller are furnished with 2 locking keys. Larger sizes have 4 locking keys.

Material Identification Mark: Two lines on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: NA0150

Material:

Insert – 303 CRES

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Inserts with an internal thread size of 1/4 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys.

Material Identification Mark: None

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51832)

Material:

Insert – A286 CRES (140 KSI Min)

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Inserts with an internal thread size of 1/4 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys.

Material Identification Mark: One line on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51832)

Material:

Insert – 4140 Alloy Steel (160 KSI Min)

Keys- 302 CRES

Finish: Cadmium Plate (QQ-P-416 Type II, Cl.2)

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Inserts with an internal thread size of 1/4 and larger are furnished with 4 locking keys. Smaller sizes have 2 locking keys.

Material Identification Mark: Two lines on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51832)

Material: 303 CRES

Finish: Passivated

Tolerances: ±.010 unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions are in inches

Keys: Integral key inserts are furnished with 2 locking keys.

Material Identification Mark: None

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914 (NAS1394 and NAS1395).

Material: A286 CRES

Finish: Passivated

Tolerances: ±.010 unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions are in inches

Keys: Integral key inserts are furnished with 2 locking keys.

Material Identification Mark: None

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914 (NAS1394 and NAS1395).

Material: 4140 Alloy Steel (160 KSI Min.)

Finish: Cadmium Plate (QQ-P-416 Type II, CI. 2)

Tolerances: ±.010 unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions are in inches

Keys: Integral key inserts are furnished with 2 locking keys.

Material Identification Mark: None

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914 (NAS1394 and NAS1395).

Material

011 – 17 – 4 PH STL

022 – 4130 STL Finish Cad Plate & DFL

031 – A286 SS Finish DFL

033 – A286 Finish Passivated

Thread Combination is determined by:

Internal Thread Class 3B + External Thread Class 2A

Internal Lock

L – Locking Feature

Blank – no locking

| Dash # | Dim “L” |

|---|---|

| -5 | .312 |

| -6 | .375 |

| -7 | .438 |

| -8 | .500 |

| -9 | .562 |

| -10 | .625 |

| -11 | .688 |

| -12 | .750 |

| -13 | .812 |

| -14 | .875 |

| -15 | .938 |

| -16 | 1.00 |

| -17 | 1.062 |

| -18 | 1.125 |

| -19 | 1.188 |

| -20 | 1.250 |

| -21 | 1.312 |

| -22 | 1.375 |

| -23 | 1.438 |

| -24 | 1.500 |

| -25 | 1.562 |

| -26 | 1.625 |

| Dash # | Dim “L” |

|---|---|

| -27 | 1.688 |

| -28 | 1.750 |

| -29 | 1.812 |

| -30 | 1.875 |

| -31 | 1.937 |

| -32 | 2.000 |

| -34 | 2.125 |

| -36 | 2.250 |

| -38 | 2.375 |

| -40 | 2.500 |

| -42 | 2.625 |

| -44 | 2.750 |

| -46 | 2.875 |

| -48 | 3.000 |

| -50 | 3.125 |

| -52 | 3.250 |

| -54 | 3.375 |

| -56 | 3.500 |

| -58 | 3.625 |

| -60 | 3.750 |

| -62 | 3.875 |

| -64 | 4.000 |

Thread Combination is determined by:

Nut End Thread Class 3A + Stud End Thread Class 2A

“D” – Crosshole

Dash – No crosshole

Material

096 – 303 Stainless Steel

097 – A286 Stainless Steel

098 – 4140 Steel

Material:

Insert – 4140 Alloy Steel (160 KSI Min)

Keys- 302 CRES

Finish: Cadmium Plate (QQ-P-416 Type II, Cl. 2)

Tolerances: ±.25 mm unless specified otherwise

Internal Threads: Per Fed Std H28/21, MJ Form

Dimensions: All dimensions below are in millimeters

Keys: Inserts with an internal thread size of M6 and smaller are furnished with 2 locking keys. Larger sizes have 4 locking keys.

Material Identification Mark: Two lines on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: NA0148

Material:

Insert – 4140 Alloy Steel (160 KSI Min)

Keys- 302 CRES

Finish: Cadmium Plate (QQ-P-416 Type II, Cl. 2)

Tolerances: ±.25 mm unless specified otherwise

Internal Threads: Per Fed Std H28/21, MJ Form

Dimensions: All dimensions below are in millimeters

Keys: Miniature inserts are furnished with 2 locking keys

Material Identification Mark: Two lines on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: NA0146

Material:

Insert – A286 CRES (140 KSI Min)

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.25 mm unless specified otherwise

Internal Threads: Per Fed Std H28/21, MJ Form

Dimensions: All dimensions below are in metric

Keys: Miniature inserts are furnished with 2 locking keys

Material Identification Mark: One line on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: NA0147

Material:

Insert – A286 CRES (140 KSI Min)

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Miniature inserts are furnished with 2 locking keys

Material Identification Mark: One line on top of insert

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51830)

Material:

Insert – 303 CRES

Keys- 302 CRES

Finish: Passivated

Tolerances: ±.010 inch unless specified otherwise

Internal Threads: Per SAE AS8879

Dimensions: All dimensions below are in inches

Keys: Miniature inserts are furnished with 2 locking keys

Material Identification Mark: None

Lubrication: Dry Film Lube on Self-Locking Inserts only

Performance: MIL-I-45914A (MS51830)