Bushing/Liner Installation Tips

(cast iron or unhardened steel jig plates)

Production accuracy requires extra care when preparing mounting holes and installing bushings/liners. The following factors should be considered: diametral interference fits, alignment, chip clearance, and how close the bushing is to the workpiece.

Because of the many variables, no definite rules can substitute for the skill and judgment of the experienced toolmaker. The following suggestions should be helpful to others.

Interference Fits

Interference Fits

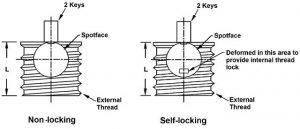

Interference holds press fit bushings in place on the jig plate. Too much interference may cause a number of problems: (1) jig plate distortion; (2) bellmouthing (bushing/ liner walls bow inward); (3) tool seizure, or (4) trouble with slip-fixed renewable fitting into the liner.

Too little interference may allow slippage, thus causing inaccurately drilled holes. In most cases, interference of 0.0005 to 0.0008 inch is sufficient to properly install press fit bushings and liners.

Mounting Hole Roundness

It is recommended that all mounting holes be jig bored or ground to assure roundness. Ordinary twist drills seldom produce an accurately sized or truly round hole!

Bushing/Liner Installation

First, lubricate the inside diameter of the mounting hole and the outside diameter of the bushing/liner – before pressing into place! Lubrication prevents scoring of the hole wall. White lead is a typical lubricant.

Second, use an arbor press to press the bushing/liner into place. If an arbor press is not available, draw the bushing/liner into place by tightening two steel plates connected by a nut and bolt. A bushing/liner should never be hammered into place! Why defeat the main purpose of the bushing? – Accuracy!

Chip Clearance

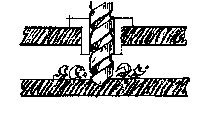

One school of thought suggests a space between the workpiece and the drill bushing. The other suggests direct contact. In order to decide, you should consider the abrasiveness of the material being drilled, the drill size, and the type of bushing/liner being applied.

Chips produced from drilling will be ejected either through a space or through the bushing. If your drill clogs or heats up, try increasing the space between the end of the bushing and the workpiece. Normal spaces vary from one-half the drill diameter for small chips (as from cast iron) to one and one-half times the drill diameter for long stringy chips (as from cold-rolled steel).

Vary the length of Slip-Fixed Renewable bushings to achieve proper spacing for your operation (see number 4 below for a more detailed explanation). A rule of thumb is, the greater the space between the bushing and the workpiece, the greater the chance for error. Where possible, test your conditions and continue to check for accuracy throughout your production run.

Hints for More Accurate Production and Longer Bushing Life

Hints for More Accurate Production and Longer Bushing Life

- Align Bushings Properly. Carefully align the drill with the bushing axis to avoid poor alignment and excessive wear. The radius on the bushing will help center the drill point. ACME No-Counterbore bushings help the operator accomplish this with ease.

- Keep Tools Sharp. Dull drill bits defeat the preciseness of bushings. Sharpen by first grinding each drill with the point in the exact center. This helps avoid “walking” by the drill when it first enters the workpiece.

- Use Proper Coolants. Check the coolant label to be sure you are using the right coolant for your machining process.

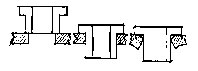

- Use Slip-Fixed Renewable Bushings for Multiple Operations. Slip-Fixed Renewable Bushings of different lengths provide for both accuracy and chip removal during multiple operations. For example, a short bushing during drilling will provide the proper clearance for chips to escape. A longer bushing during reaming will provide maximum guidance.

- Adapt Bushings To Irregular Work Surfaces. The exit end of the bushing should conform to contours of the workpiece. For maximum guidance, hold to a minimum any space for chip clearance. A drill point that does not enter exactly perpendicular to the work surface will skip or wander. In such a case, side load exerted by the drill is concentrated near the exit end of the bushing. The bushing can wear prematurely. Slip-Fixed Renewable bushings could simplify replacement of worn bushings, and also aid alignment with the contoured work surface. For short production runs using press fit bushings, form the bushing end to the workpiece contour.

- For Long Production Runs, Use Tungsten Carbide or Titanium Nitride Coated Bushings. ACME Carbide bushings last up to 50 times longer than hardened steel. ACME Titanium Nitride (TiN) coated bushings can last up to 40 times longer than conventional bushings. Both types of bushings could save valuable replacement downtime. The additional cost is small when you consider the extra long life possible. Call us for more details.